Tel Number

180-3717-8440

Company Statement" Zhengzhou KJ Technology Co., Ltd. " belongs to the international business department of KJ Group. Starting today, the company will continue the international business contract signed or currently being performed by " Zhengzhou Kejia Furnace Co., Ltd. " See details >>

Description:

The furnace is professionally used for laboratory calcination and drying of some positive electrode materials such as battery iron aluminum phosphate, powder materials without strong acid and alkali, and granular materials.

| Model | KJ-TX1000-L150CK3W |

| Furnace structure | Carbon steel outside shell Alumina fiber lining Double-layer structure with cooling fan Split type |

| Continuous working Temperature | ≤1000℃ |

| Heating Rate | 0-20℃/min, Suggestion 0~10℃/min |

| Temperature Zone | Three heating zone |

| Heating zone length | 400+400+400mm, total length 1200mm |

| Tube size | OD150mm x L2400mm |

| Heating Element | SiC rods |

| Temperature Control Accuracy | ±1℃ |

| Tube rotating Speed | 0 - 5RPM variable |

| Furnace Tilt Angle | 0~5° |

| Thermocouple | 3 pieces of K type |

| Max.heating Power | 26KW(Specific according to design) |

| Tube material | Inconel 601(with lifting blade inside) |

| Chamber material | Alumina Fiber |

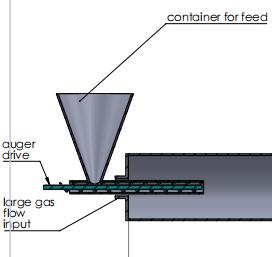

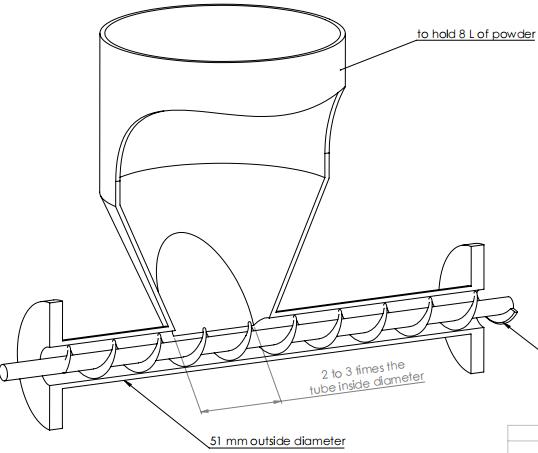

| Left side |

-8L of SS304 stainless steel of container; -Auger drive for material feeding (SS316 stainless steel); -N2 Gas inlet; -SS304 stainless steel cover for relative sealing. |

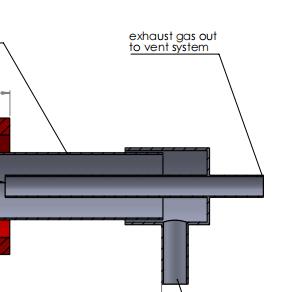

| Right side |

-4L of SS304 stainless steel of container, both top and bottom with valves; -OD35xL600mm Inconel 60l tube on the right side for exhaust gas out(with diameter 50mm flange connection port). -SS304 stainless steel cover for relative sealing. -N2 Gas inlet; |

| Temperature Controller | 3 pieces of Eurotherm 3504 temperature Controllers |

Mass flow meter |

MFC 1: 0-2000sccm, N2 MFC 2: 0-20000sccm, N2 Installed with 2 stainless steel needle valves. Accuracy: ±1.5 % F.S Linear:±(0.5~1.5) % F.S Repeatability:±0.2 %F.S Response time : Electrical Characteristics: 10 sec Gas Characteristics: (1 ~ 4) sec Working pressure range:(0.1 ~ 0.5) MPa Operating ambient temperature:5 ℃ ~ 45 ℃ Input and output signals:0 V ~ +5.00 V (Input impedance is > 100K, output current < 3mA) |

| Warranty | One year limited warranty |

Rotary Tube Pyrolysis Furnace - For Engineering Plastic Pyrolysis

Pilot-scale rotary kilns have helped US customers innovate in new energy, enabling them to successfu

Malaysian customers came to our factory to inspect the magnetron sputtering coating equipment

PECVD for carbon nanotube growth

Research group of Tsinghua University in China visited the factory

Professional Process, Effortless Purchase

Click to inquire

E-mail:web@kejiafurnace.com

E-mail:web@kejiafurnace.com

Tell:+(86) 18037178440

Tell:+(86) 18037178440

Whatapp:+(86) 180-3717-8440

Whatapp:+(86) 180-3717-8440

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone

Address:Room 1505, Building 9, No. 26 Dongqing Street, Zhengzhou High-tech Industrial Development Zone

Tel Number

180-3717-8440

web@kejiafurnace.com

YouTuBe